Quartz microbalance (QCM): principle of use

Quartz microbalance (QCM) are used to measure, in situ and in real time, the thickness of thin films during vacuum deposition.

Principle of use:

The measurement is based on the modification of oscillation frequency of the piezoelectric crystal due to mass overload. Thus, when a material thin film is deposited on the surface of a quartz crystal, its resonance frequency varies in a proportional way of the deposited layer mass/weight. We mainly use 5Mhz or 6 Mhz AT-cut quartz. The 6 MHz quartz are dedicated to most recent deposition systems while the 5 MHz are typically used in BALZERS and equivalent evaporators.

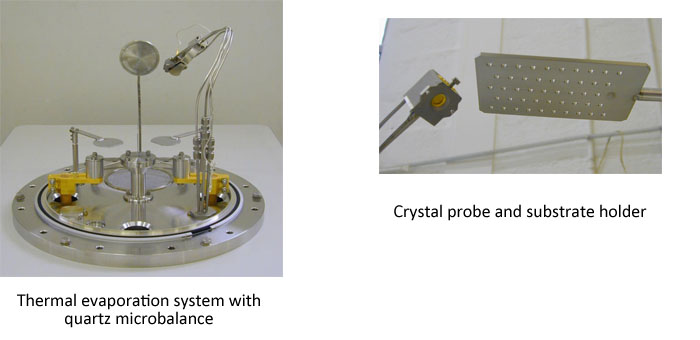

The quartz probe has to be installed inside the vacuum chamber, close enough to the substrate where the deposit will be performed (refer to the picture below). Knowing the density of the layer, the thickness of the layer is then calculated in real time. Initial measurements as micro-weight (or nano-weight for very thin layers) or thickness on the substrate allow to pre-calibrate the system.

Neyco supplies two types of measurement chains by microbalance :

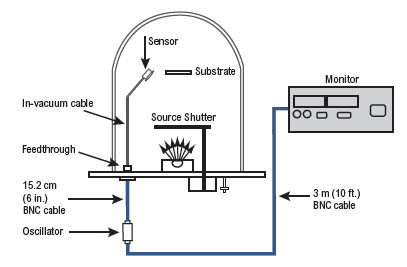

1) Quartz Microbalance with Oscillator, including :

- 1 water-cooled quartz probe

- 1 watercooling feedthrough with 2 tubes + 1 coaxial cable to connect the quartz to the external oscillator

- 1 electrical oscillator mounted as close as possible to the vacuum feedthrough (thus to the quartz)

- 1 controller or monitor

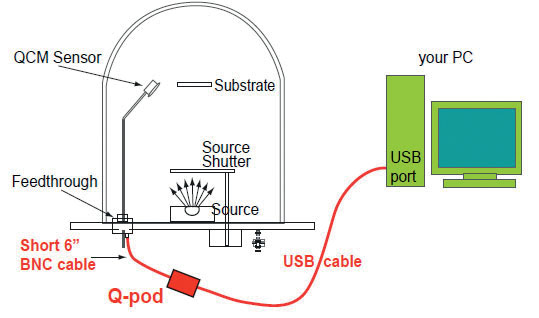

2) Quartz Microbalance (QCM) with a Q-pod (also known as QPOD and STM-2) :

The Q-pod replaces both the oscillator and the monitor, and allows the data acquisition directly with the dedicated software.

If you want an offer, or for more information about this product: Contact us

_1673427121.png)