Liners for MBE

Information guide

Molecular beam epitaxy (MBE) is an ultra-high vacuum (UHV) thin film deposition technique. MBE is widely regarded as the most controllable and purest form of deposition. It is currently used in both R&D and production. Most MBE growths result in high quality epitaxial thin films.

In molecular beam epitaxy, solid sources of high purity growth material (5N+) are placed in crucibles, usually made of pyrolytic boron nitride (PBN).

PBN (pyrolytic boron nitride, pyrolytic BN) ceramic is kind of advanced ceramic, and it can be produced with 99,999% purity by the chemical vapor deposition (CVD) fomation method. The use of traditional hot pressing sintering process is not necessary. PBN ceramics have excellent chemical inertness, high purity, low outgassing, thermal stability, as well as non-wetting characteristics and a long service life.

These crucibles are heated to the evaporation temperatures required for the evaporation of the material used, which causes a flow of vapor from the evaporated material towards the substrate on which the deposit is to be made. Mechanical or pneumatic shutters are placed just above the crucibles, which allow a precise and sudden control of the deposition process.

PBN crucibles are ideal for MBE (molecular beam epitaxy). They provide excellent flow uniformity over the treated surface during the entiere process. They are designed for liquid melts of group 3 metals, e.g. gallium, indium and aluminium.

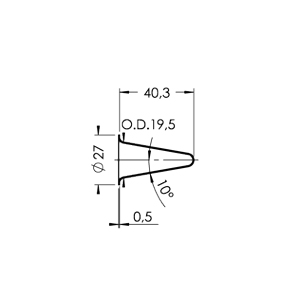

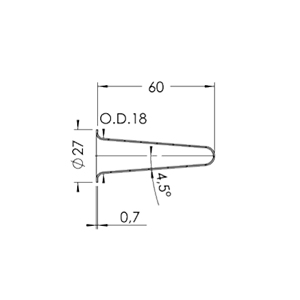

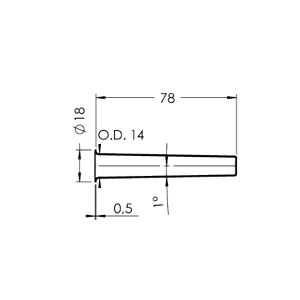

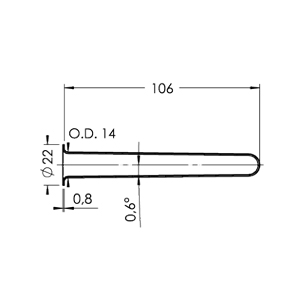

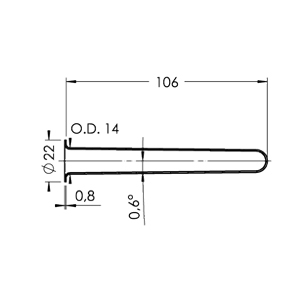

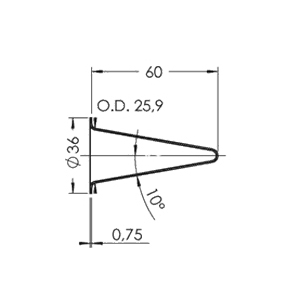

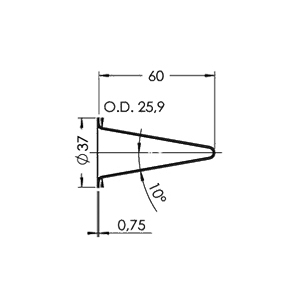

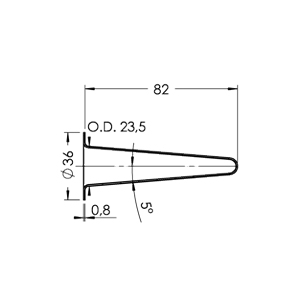

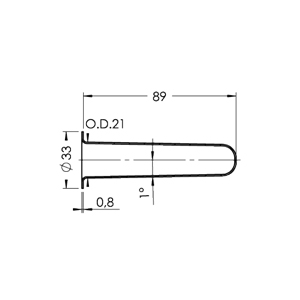

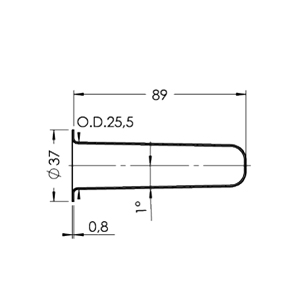

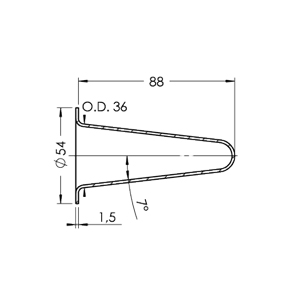

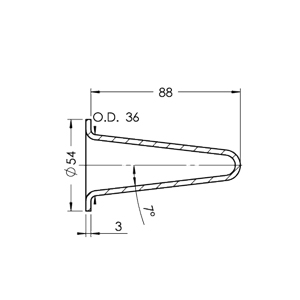

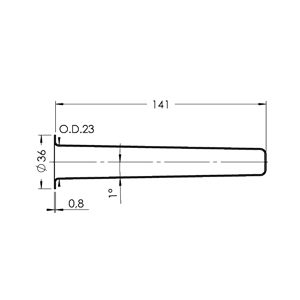

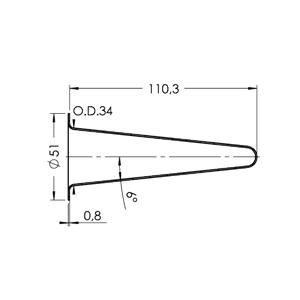

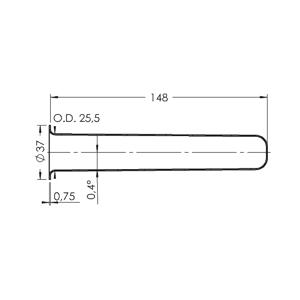

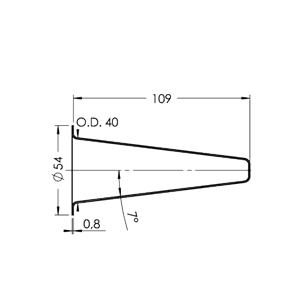

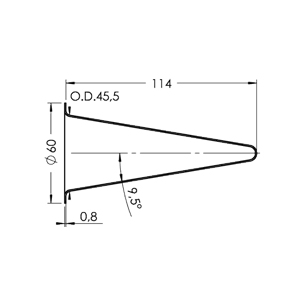

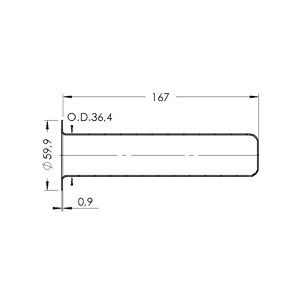

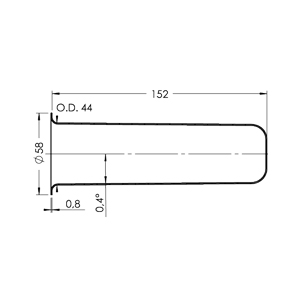

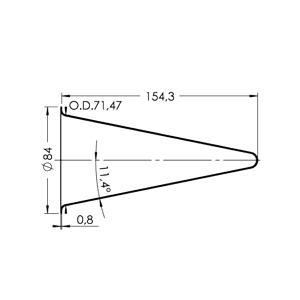

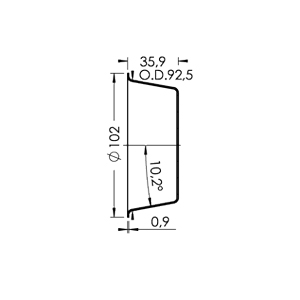

These crucibles consist of two elements :

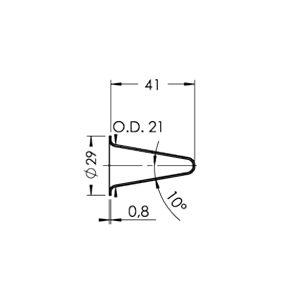

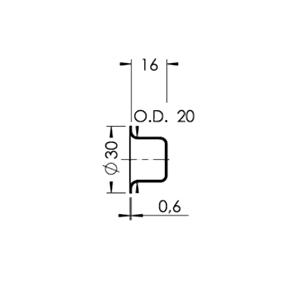

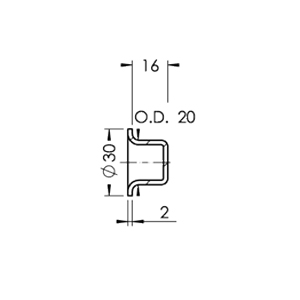

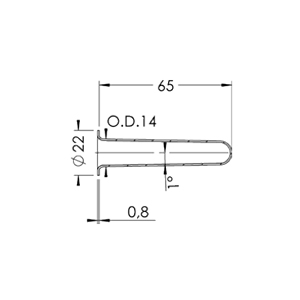

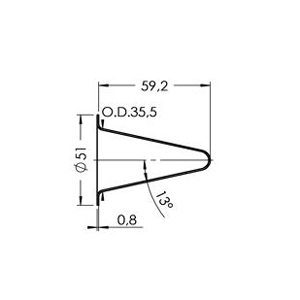

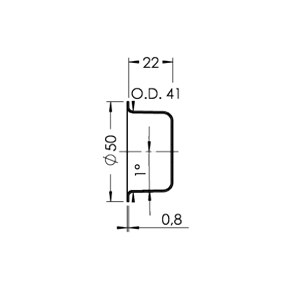

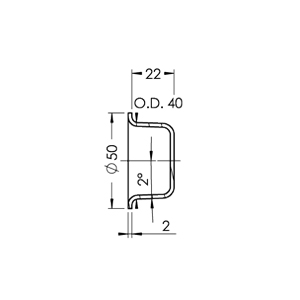

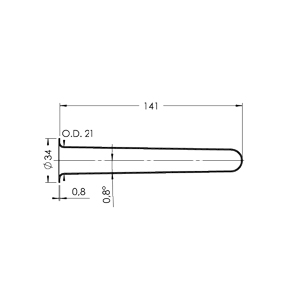

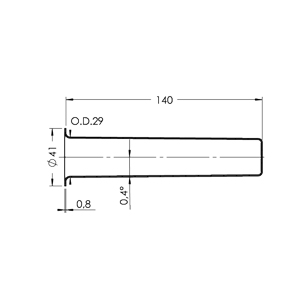

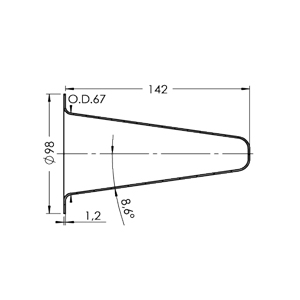

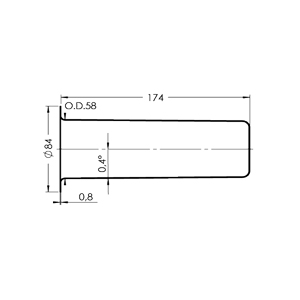

- The conical element allows an increase of the thermal impedance between the surface of the melt and the interior of the MBE system, thus reducing the transient flux and thus promoting the uniformity of the molecular beam over the treated area during the operating time.

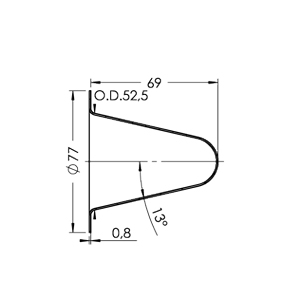

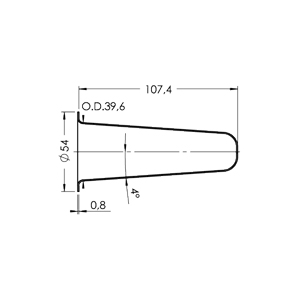

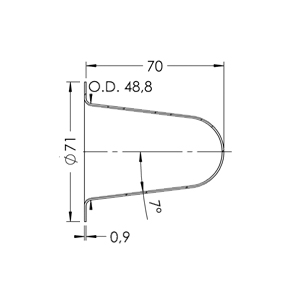

- The outer element contains the melt, it is typically cylindrical and its maximum capacity must be compatible with the furnace interior. The inner element has a conical configuration with a small opening at the bottom which allows for optimal molecular beam formation.

The purity of the evaporated material and the ultra-high vacuum environment (base pressures in the MBE are typically 1 x 10-10 mbar or less) results in an extremely pure evaporated material deposit. With precise control of the substrate temperature, true atom-by-atom deposition can be achieved.

_1673427121.png)